Been a while since my last update here...

Last thing I made is this DJI Inspire 1 - 10inch tablet holder. The files are on Thingiverse.com!

Me building a RepRap 3D printer - a Prusa Mendel iteration 3 - as a complete and inexperienced noob.

Showing posts with label 3dprint. Show all posts

Showing posts with label 3dprint. Show all posts

31 March, 2015

16 March, 2015

Custom Antenna cover for a Porche!

Designed by my brother XyZeR, printed and smoothed by me: A custom fin to cover the antenna on a Porche.

The part was printed in ABS, smoothed using a hot acetone vaport bath, then further sanded and painted. Glued with TEC7 to the roof.

|

| Porche Antenna - 3d printed |

13 July, 2014

08 July, 2014

Emmet's Three Cube Gear

I already printed some objects from Thingiverse created by Emmet. Now I printed Emmet's Screwless Three Cube Gear.Total print time around 5 hours. ABS @ 245°C with a 200µm layer height. Customized with Thingiverse's customizer and sliced with Slic3r.

03 July, 2014

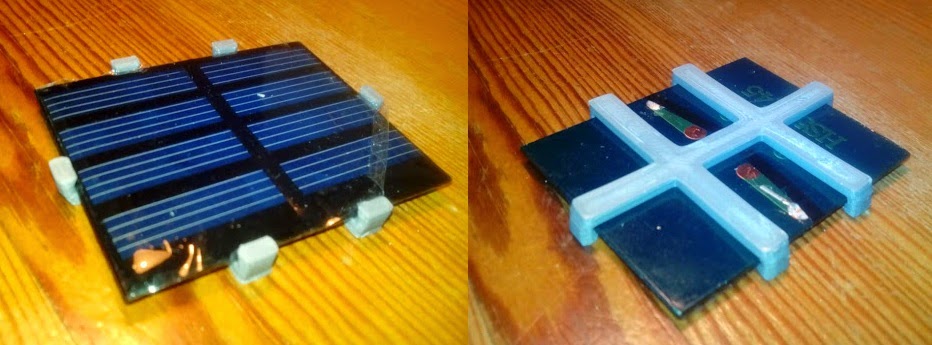

Solar Cel clip for a DIY sunjar

My friend Richard is working on a DIY project making a Sunjar.

After creating the solar cell holder clip in Sketchup we printed it on the RepRapin ABS.

Very happy with the end result he's now going to make six more Sunjars!

(ToDo: Post link to STL file)

24 June, 2014

From pictures of a face to a 3d head

Going from pictures of a face to a 3d printed head.

Step 1 - Use FaceGen Modeler's Photofit feature to generate a 3d-mesh and a uvw-map of the skin.

|

| UVW-map of the face generated with FaceGen Modeler |

|

| The whole head is exported from FaceGen as an OBJ-file and can be imported in any 3d modeling software. |

Step 3 - Print it!

A timelapse of the 3 hour print....

23 June, 2014

Reprap to the rescue: Fixed my daughter's favourite toy

|

| Original Broken & Newly 3d printed lever |

My oldest daughter's favorite toy is the Fisher Price Sink Set (1982). It's a toy that my wife used to play with when she was a toddler so it's quite old (no darling you're not old!) but still in good shape. Recently my daughter was upset because water stopped coming out when she pushed the lever. I opened up the set and noticed a broken lever that pushes a rubber pump.

So let's fire up Sketchup and get the calipers ready and start drawing! Then generated an STL file (you need a plugin to generate STL files in Sketchup) and sent it to the Prusa I3 reprap.

I know one little person who will be very happy when she wakes up in the morning...

Let me know if you need the STL files. I printed in ABS with layer height @ 200µm and Slic3r Honeycomb infill @ 80% with a tiny bit of Brim (2mm)

06 June, 2014

My first 3D print with PLA - a Gear Bearing

To test the PLA material I never printed with until now I printed some planetary gears.

This is a customized version of Emmet's Gear Bearing on Thingiverse. The tolerance is set to 0.3 in the customizer. I'll print another one with 0.1 as these are even a bit too loose...

Printed in PLA, extruder @ 200°C, heatbed @ 65°C, layer height 200µm, (still no cooling, I really need to connect my PLA extruder fan to my electronics!)

This is a customized version of Emmet's Gear Bearing on Thingiverse. The tolerance is set to 0.3 in the customizer. I'll print another one with 0.1 as these are even a bit too loose...

Printed in PLA, extruder @ 200°C, heatbed @ 65°C, layer height 200µm, (still no cooling, I really need to connect my PLA extruder fan to my electronics!)

Labels:

3dprint,

Calibration,

PLA,

Prusa Mendel i3,

thingiverse

27 May, 2014

Panelolu2 and the new Marlin firmware (T3P3 fork)

Upgraded my Prusa i3 with a Panelolu 2 display/controller.

The display has an SD-card slot so no need to keep a computer running while printing. You can print G-code right off the sd-card. Saves on power consumption as well!

While printing you can also monitor and change the temperatures for the heatbed & extruder and change the power to the extra extruder fan (needed for PLA).

Because of the 'adapter board' you can plug the LCD into the Sanguinololu without soldering or adding components.

You do need to add an LCD library called Lincomatic to the Arduino IDE and flash updated Marlin firmware to the ATmega 1284P chip. The T3P3 Marlin fork can be found on GitHub.

Full Panelolu2 installation instructions are available at Think3dPrint3d 's blog. When the instructions say: "Don't use Arduino 1.x", then don't! Marlin was originally designed for Arduino 0.23 and does not work on 1.x, trust me...

I've bought the electronics from Richard @ RepRapUniverse.com.

The case for the BPC can be found on Thingiverse and can be printed yourself.

|

| The Panelolu 2 electronics & adapter board |

|

| Printing the case for the Panelolu 2 Display |

|

| The adapter board connecting the Panelulo2 display to the Sanguinololu |

|

| A working Panelolu2 after flashing new Marlin(T3P3) firmware to the ATmega1284p |

To test the new firmware and electronics I decided to print the 50mm 'torture' bridge in ABS. All seems to work fine!

Next step: Print some PLA...

18 May, 2014

Dr Who - War Doctor - 3dhubs.com

My first print for 3dhubs.com arrived via my 3D-Hub. It's a Dr Who character, the War Doctor.

This was my first print with Support Material generated in Slic3r, it works way better as I expected. You have to remove the support material afterwards and it may leave some scars behind.

The War Doctor on Thingiverse: the Remixed version works fine, the original isn't printable due to lots of errors in the meshes.

This was my first print with Support Material generated in Slic3r, it works way better as I expected. You have to remove the support material afterwards and it may leave some scars behind.

The War Doctor on Thingiverse: the Remixed version works fine, the original isn't printable due to lots of errors in the meshes.

A time lapse video of 3d printing the War Doctor including support material - Print time was 6,5 hours

Labels:

3dhub,

3dprint,

ABS,

Prusa Mendel i3,

Slic3r,

support material

12 May, 2014

New Prints - An Ingress Portal Key and a personalized guitar pick

Some new prints:

Next I'm planning on attaching the Panelolu 2 Display I've been having for a couple of weeks now to start printing with PLA. The extra extruder fan can be controlled with header outputs on the Panelolu2 PCB. For now I've been printing only with ABS. I'm now reading on how to connect, configure and use the display with Sangiunololu and Marlin Firmware.

*TWEX = The Wednesday Evening eXcuse

|

| Ingress Portal Key for an Ingress Resistance player |

|

| A guitar pick for TWEX's guitar player & rockstar Bjorn V.G. |

*TWEX = The Wednesday Evening eXcuse

06 May, 2014

Don't forget to print spare parts for your reprap!

I almost forgot to print spare parts for my Prusa i3 RepRap. I decided to first print the extruder herringbone gears as they seem to wear the most.

I'm very happy with the quality of the printed herringbone gears.

Let me know if you need spare parts for your RepRap!

It's been a while since I posted a video of the printer in action...

On my PC I use a webcam viewer app and TeamViewer is active so I can check on a print using my SmartPhone / Tablet / PC from anywhere in the world! And it's free.

23 April, 2014

Just printing some stuff, no calibration this time...

The Droplet Vase from Thingiverse. The top is not very good due to the issue described in the previous post.

I kept losing my drills, so made this object in Sketchup (I need to try other software soon), sliced with the new Slic3r 1.0.1 and printed with PrintRun Pronterface.

Note to self: do not print a 3mm hole for a 3mm object, use spacing!

I kept losing my drills, so made this object in Sketchup (I need to try other software soon), sliced with the new Slic3r 1.0.1 and printed with PrintRun Pronterface.

Note to self: do not print a 3mm hole for a 3mm object, use spacing!

Bad print quality on small lines/area's/bridges + Custom made adjustable Z-endstop

My <5mm = bad print quality issue

While printing smaller objects the prin quality is really bad. Rounded corners that should be straight corners, ugly 5mm bridges while I can print a perfect (imho) 50mm bridge. etc.So i've asked the people on the RepRap Forums for their experienced advice...

Custom made adjustable Z-endstop

A friend created a custom made adjustable z-endstop in a fancy CAD program. The print is not perfect yet (due to the issue described above) but a second version of the STL files is coming soon. If it works out fine I'll post the STL's on thingiverse!11 April, 2014

Bracelet for my girlfriend

For my mothers' wedding my girlfriend asked me to print a black bracelet. So I've ordered some black ABS from Charlie and printed this bracelet from Thingiverse by Nervoussystem.

My girlfriend and me were happy with the result.

My girlfriend and me were happy with the result.

|

| My beautiful girlfriend with our self printed bracelet. |

10 April, 2014

Calibrating > Bridging @ 30mm/s

To print the 5mm bridge I've set the bridge printing speed to 30mm/s (in Advanced settings of Slic3r). I was very happy with the first result.

|

| 50mm bridge @ 30mm/s |

07 April, 2014

Calibration calibration calibration...

|

| Perimeter Width - Calibration |

|

| Oozebane & Bridging calibration |

|

| Bridging Calibration - This box is hollow. |

|

| Marvin v1 & v2 |

02 April, 2014

Printed Marvin for a review on 3dhubs.com

I've listed my printer on 3dHubs.com so people can pay me to print items for them.

To get a first review you are asked to print 'a Marvin keychain'. I'm not very happy with the result so I'll first do more calibrating and then give Marvin another go soon.

Check my 3d Print Hub here!

Object: Marvin - 20140205_Marvin_KeyChain.STL

Hotend: 245°C 1st layer, then 240°C

Heatbed: 110°C

Material: 3mm ABS

Layer height: 0.2mm

Wall thickness: 0.4mm

Infill: 25%

To get a first review you are asked to print 'a Marvin keychain'. I'm not very happy with the result so I'll first do more calibrating and then give Marvin another go soon.

Check my 3d Print Hub here!

Object: Marvin - 20140205_Marvin_KeyChain.STL

Hotend: 245°C 1st layer, then 240°C

Heatbed: 110°C

Material: 3mm ABS

Layer height: 0.2mm

Wall thickness: 0.4mm

Infill: 25%

31 March, 2014

Calibration - Layer Height

To continue the RepRap calibration process (yes you really need that much calibration) I printed an object to verify the Layer height.

The object printed perfectly but I noticed my wall thickness is 0.75mm instead of 0.40mm. Something that needs some investigation. I also verified that the X and Y axis calibration is perfect now; 20mm in any software gives an object of exactly 20mm!

Object: 4-mm-wall.stl by muelli from Thingiverse

Hotend: 245°C 1st layer, then 240°C

Heatbed: 110°C

Material: 3mm ABS (Silver from RepRapUniverse.com)

Layer height: 0.2mm

Wall thickness: 0.4mm

Infill: 100%

Static props: 0.4mm nozzle, E3D All metal hotend, MK2a heatbed, Gcode generation with Slic3r, Pronterface, Sanguinololu, Ice Blue Stepsticks, NEMA17 motors, Prusa i3, Achatz Edition, ATX powered 400W

The object printed perfectly but I noticed my wall thickness is 0.75mm instead of 0.40mm. Something that needs some investigation. I also verified that the X and Y axis calibration is perfect now; 20mm in any software gives an object of exactly 20mm!

Object: 4-mm-wall.stl by muelli from Thingiverse

Hotend: 245°C 1st layer, then 240°C

Heatbed: 110°C

Material: 3mm ABS (Silver from RepRapUniverse.com)

Layer height: 0.2mm

Wall thickness: 0.4mm

Infill: 100%

Static props: 0.4mm nozzle, E3D All metal hotend, MK2a heatbed, Gcode generation with Slic3r, Pronterface, Sanguinololu, Ice Blue Stepsticks, NEMA17 motors, Prusa i3, Achatz Edition, ATX powered 400W

Subscribe to:

Comments (Atom)

.JPG)